|

|

Just for the sake of having it, neither I nor this site have any affiliation with Lego, Lego group, Lego systems or Lego MindStorms. Also, I am not responsible for any damage to your RCX and/or computer that may result from the use of the knowledge/designs stored on this WebSite.

In the text of my first design (the Temp

Sensor) I stated the following:

"After acquiring my MindStorm's robotic invention system

I began performing tests on the brick to see if any the theories

I had (for future sensors) were feasible. I quickly discovered

the four basic modes. (Touch, Light, Rotation & Temperature)"

For myself, one of the biggest downsides to the RCX is the lack

of input and output ports. In some of my earlier projects I attempted

to overcome this limitation by designing sensors

& motor/light blocks that allowed

more devices to function on each port. The result, unfortunately,

meant that the user had to exponentially complicate their program

code to accommodate the new motor/sensor sharing scheme. A prime

example of this is my second project (the

resister pad). My third project (the

motor/light block) was my first attempt at expanding the output

ports. While this did give you two output ports from one it was

only one direction & in "Float" mode. ("Float"

meaning 'slows to stop' and not 'stops immediately' as in "Brake"

mode.)

I'm very Pleased to announce that my latest project the '(MS)2

Expander' will expand your RCX's ports with very little additional

programming. Some of the possibilities are as follows;

1. 6 Full featured output ports!

(3 banks of 2 output ports with 2 usable at any one time with

full "Brake"/"Float" & Direction abilities)

2. 3 + 1 Full featured output ports & 3 + 2 Full featured

input ports!

(3 banks of 1 output port + 1 RCX direct port & 3 banks of

1 input port + 2 RCX direct ports)

3. 6 + 1 Full featured input ports! (At the loss of 1 output port)

(3 banks of 2 input ports with 2 usable at any one time + 1 RCX

direct input port)

As you will see, this device can be used simultaneously with input

& output ports with the only expense being one output port

for the controlling of the device. (The workings will be better

explained below.) Also, if you use two of the (MS)2 Expander you

can have 6 Outputs and 6 (+1 Direct) Inputs! All for the same

use of the single motor port.

Premise

First, like my last three projects (the

Temperature Sensor, the Sensor

Pad & the Motor/Light block),

this project uses the Lego Electric Plating (part #5037) for the connectors.

You will need (Parts)

You will require the following components;

Lego components:

2x 2 by 8 electric plating (#5037)

1x 2 by 4 electric plating (#5037)

4x 1 by 4 brick (white)

4x 1 by 8 brick (white)

1x 4 by 10 plate (gray or white)

Non Lego components:

4x In4148 diodes

2x 6 - 9v DPDT Relays (see below on part numbers for this item)

Perforated circuit board -- approximately 8 studs long by 2 studs

wide

Assorted wire approximately 22 to 24 gauge

Glue (I used five-minute epoxy)

Some kind of labeling system (If desired)

A note on Relays

The required type of relay must be able to function with a voltage

range of 6 to 10 volts. (The RCX's output voltage changes depending

on the battery condition or the external power adaptor used.)

Your choice of relay must be able to work in these conditions.

Get one too high and the relay might not have enough power to

trip or stay tripped. Get one too low and you'll burn out the

relay after an amount of time.

Here is a link

to a web site that has relays. The type listed as HRS2H-S-DC9V

has an operating voltage of 6.75 volts. Sounds good doesn't it?

BUT, we must take into account the 1.2 volt loss from the two

DIODES that allow us to trip only one relay. (.6 volts per diode

if you used the ones I have listed.) It is up to you on what Relays

you use. Also, each Manufacturer has different variances on their

parts. You must study them and make your own adjustments as needed.

Perhaps using 6v relays (Part # HRS2H-S-DC6V with a operating

voltage of 4.5 volts) and doubling up on the diodes to keep it

within tolerance would work better for you? I hope this helps

clarify relays a little better.

How to construct this project

First,

you should design your enclosure. For my design, I chose a 10

by 4 by 2.2 design. (2.2 = 2 bricks & 2 plates) this allows

my project to have all the connections on top. You can, of course,

design yours any way you see fit. Just make sure that your design

leaves enough room for the necessary components inside and that

the wires will have access to the electric plating. (The next

time I build one of these I will use a white technic beam in place

of one of the 1x8's. This will allow it to be attached to my creations

in a way similar to the RCX.)

First,

you should design your enclosure. For my design, I chose a 10

by 4 by 2.2 design. (2.2 = 2 bricks & 2 plates) this allows

my project to have all the connections on top. You can, of course,

design yours any way you see fit. Just make sure that your design

leaves enough room for the necessary components inside and that

the wires will have access to the electric plating. (The next

time I build one of these I will use a white technic beam in place

of one of the 1x8's. This will allow it to be attached to my creations

in a way similar to the RCX.)

For the rest of this document I will assume you are following

my general case design.

Once

your enclosure is completed and you have performed a test fit

of all of the Lego components to ensure that they do not collapse

inward upon themselves it is time to design the circuit board.

Once

your enclosure is completed and you have performed a test fit

of all of the Lego components to ensure that they do not collapse

inward upon themselves it is time to design the circuit board.

Measure

out the approximate dimensions of your enclosure and select the

most likely position for the circuit board. Then, cut the circuit

board to measure. It is important to test fit each of the components

to ensure they will fit properly on the circuit board and that

their dimensions will all fit in your enclosure. (Be sure to leave

adequate room for the wires that will be attached to the electric

plating.)

Measure

out the approximate dimensions of your enclosure and select the

most likely position for the circuit board. Then, cut the circuit

board to measure. It is important to test fit each of the components

to ensure they will fit properly on the circuit board and that

their dimensions will all fit in your enclosure. (Be sure to leave

adequate room for the wires that will be attached to the electric

plating.)

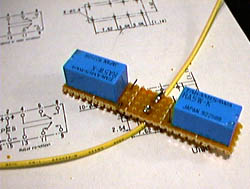

Now

solder the relays and diodes (observing the proper polarity) onto

the circuit board as seen in the picture. (Be sure to examine

the schematic before you begin so

you completely understand the procedure.)

Now

solder the relays and diodes (observing the proper polarity) onto

the circuit board as seen in the picture. (Be sure to examine

the schematic before you begin so

you completely understand the procedure.)

Once the above is completed you must attach a wire to each of

the opposing diode joinings. This is difficult to explain and

I strongly suggest you consult the schematic.

For this example I used a yellow wire. Once these wires are in

place you should test your relays to ensure that only one triggers

at a time depending on the polarity of the RCX. (I.e. Forward

or Reverse) If none or both trigger at the same time you have

a short or the relays/diodes are in the wrong orientation. It

is critical that this works as the schematic dictates.

The two wires are then to be soldered to the 2 by 4 electric plating.

This is the input that triggers the device.

The (MS)2 Expander has three possible states.

Default state, bank one is active.

Positive power state, bank 2 is active.

Negative power state, bank 3 is active.

(The Positive and Negative banks depend on which way the device

is connected to the RCX output port)

The

inside wall of the 1 by 4 brick on which the above 2 by 4 electric

plate will sit must be removed. (See photo) This is to allow the

wires access to the plate and to allow the plate to sit firmly

in place. You must leave enough of this brick to allow proper

gluing.

The

inside wall of the 1 by 4 brick on which the above 2 by 4 electric

plate will sit must be removed. (See photo) This is to allow the

wires access to the plate and to allow the plate to sit firmly

in place. You must leave enough of this brick to allow proper

gluing.

The

two 2 by 8 electric plating pieces must now have their respective

inside metal tracks cut in three places. Carefully cut the underside

metal on the inside track as seen in the photo. (This can be quite

difficult to achieve. Consult the sensor

pad project if you require a more detailed photo) The red

circled areas in the photo show the places that you must cut.

You MUST ensure that no current can get from one segment to the

other. It is imperative that this is done with extreme care. Cutting

the metal track is not an easy task.

The

two 2 by 8 electric plating pieces must now have their respective

inside metal tracks cut in three places. Carefully cut the underside

metal on the inside track as seen in the photo. (This can be quite

difficult to achieve. Consult the sensor

pad project if you require a more detailed photo) The red

circled areas in the photo show the places that you must cut.

You MUST ensure that no current can get from one segment to the

other. It is imperative that this is done with extreme care. Cutting

the metal track is not an easy task.

You may be wondering why you do not have to cut the outside metal

track on each of the two 2 by 8 electric plates. This is because

they are to be the common (or GROUND) connection. All three banks

will have this one connection in common. It is the active (or

HOT) connection with which we will be switching between the three

banks.

You

must now solder wires to each of the output pins on the relays.

(Please note the special configuration of the wiring going from

one relay to the other. This is how we do the default (bank 1)

state.) It is helpful here to use different colour wires. Make

sure you do the same for both sides. This will avoid confusion

in the future. Connect each of the wires to the inside segments

of the 2 by 8 electric plating. Please ensure that you put the

same bank in the same location on both sides to avoid confusion.

You

must now solder wires to each of the output pins on the relays.

(Please note the special configuration of the wiring going from

one relay to the other. This is how we do the default (bank 1)

state.) It is helpful here to use different colour wires. Make

sure you do the same for both sides. This will avoid confusion

in the future. Connect each of the wires to the inside segments

of the 2 by 8 electric plating. Please ensure that you put the

same bank in the same location on both sides to avoid confusion.

Once all six wires are firmly in place test to ensure that there

are no shorts between the plating segments and then test the relays

to ensure that the proper banks are active at the proper times.

Once

everything is functioning as it should be, perform a test fit

by putting everything into the enclosure and squeezing it together.

Re-test the entire device again.

Once

everything is functioning as it should be, perform a test fit

by putting everything into the enclosure and squeezing it together.

Re-test the entire device again.

Now carefully pry each segment apart one at a time, glue the device

together and allow it to dry. (Five-minute epoxy takes approximately

24 hours to fully harden)

Congratulations! You just created one of the most useful devices

I've designed to date.

That's about it, if you have any questions you may contact me

via email. Enjoy!

[RETURN] to TFM's Home Page